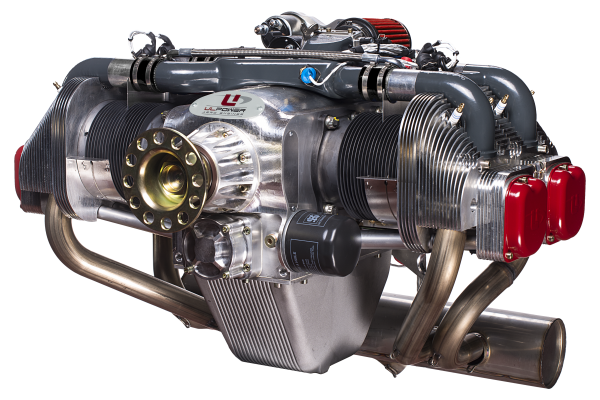

UL520T available as ASTM compliant version.

ULPower Aero Engines, have been spinning props since 2006. Up to now, these engines have been categorized as “experimental”.

The newest UL520T however , which was released for commercial production in January 2021, is also available as ASTM version. Since the UL520T is basically a normal UL520 but now with turbo charger, the ASTM version is also available for the UL520i an UL520IS.

What does ASTM compliant mean ?

ASTM was originally known as the American Society of the International Association for Testing and Materials when it was created in 1898 by Pennsylvania Railroad engineers and scientists. Its purpose was to address and prevent the frequent rail breaks that were plaguing the industry by developing standards that would ensure higher quality rail products.

Today, ASTM develops and publishes technical standards with the goal of enhancing performance and safety over a wide range of products, materials, systems, and services. Thousands of ASTM standards are upheld all over the world, each with their own unique number.

ASTM F2339

ASTM F2339 describes the minimum requirements for the design and manufacture of reciprocating spark ignition engines for light sport aircraft and has been accepted by the FAA and EASA .

The UL520T is designed ,produced and tested in accordance with the ASTM F2339-19 standard.

This standard is basically a quality standard similar to ,for example, ISO9001 but ASTM also covers more technical criteria which are similar to the EASA(CS-E) standard.

The main difference between ASTM and EASA is that the test runs are not supervised by an EASA official.

An ASTM product certification is not only “product based” but also covers a continued production quality control system forcing the applicant to a defined level of traceability.

A complete design control system with implementation of processes and a quality control system are essential to achieve the Declaration of Compliance.

Following tests have been carried out (and passed) to meet the standard:

Data Requirements:

- Manuals, parts list, traceability have been updated.

Design criteria :

- Material specification sheets were created.

- Fuel and Induction System is designed to minimize the accretion of ice, to prevent obstruction of air or fuel, to prevent damage from hydraulic lock on starting, to prevent fire.

- Dual ECU system to accommodate single failures of the electrical circuit (DO-160 / DO-178 / DO-254 / ASTM F3153 )

- Ignition system with a dual-ignition system with at least two spark plugs for each cylinder and two separate electric circuits with separate sources of electrical energy was designed.

- Lubrication System is designed and constructed so that it will function properly in all flight attitudes and atmospheric conditions in which the engine is expected to operate.

- Calibration, vibration, detonation, accelerated overhaul (an endurance test that simulates TBO) and ultimate load test were done

Concession evaluation system which covers

- A traceability system for materials and parts

- Inspection criteria for all parts

- Assembly and acceptance testing process

A document with an overview of the ASTM requirements, the EASA requirements and how ULPower deals with the requested quotas is available upon request.

The UL520TC engine is essentially the same but comes with dual ECU, and goes through further documentation to achieve ASTM F2339 compliance.

It goes without saying , that the entire range of ULPower engines will somewhat benefit from this approach, since there is a huge communality of parts amongst all type of engines.