CHT Sensors/Senders

Installing CHT (Cylinder Head Temperature) and EGT (Exhaust Gas Temperature) sensor/senders onto your ULPower engine is not a difficult task, but it is important to get them installed correctly if the readings are to be useful to you as a pilot or engineer.

The ULPower Engine Control Unit (ECU) does NOT monitor the EGT nor the CHT temperatures, and does NOT use them in either MAP or error generations. This leaves the monitoring to the pilot, and allows for the use of either analogue gauges or a feed into a digital instrument of some kind (EFIS, or stand alone). EGT and CHT values are, apart from the use of power and pitch, in essence, outside of the control of the pilot once in normal flight. However, it is very much the responsibility of the builder to establish a good installation to ensure that the values remain in range during normal flight ops, which is then checked and tweaked as part of the test flight programme. During the initial testing of a new type/configuration of aircraft, there will be a number of flights needed to optimise the installation – this is where the EGT and CHT values provide an essential feedback with regards to the efficiency of the installation, giving the builder a chance to adjust baffles, cowlings, NACA ducts, etc to find that sweet spot for the ULPower installation to that airframe. In the ideal installation the CHT values should be within a few degrees of each other.

The CHT limits are laid out in the Operations Manual (available from www.ulpower.com) and are the same values across the range of engines:-

Cylinder Head Temperature

Min. 50°C (125F) (below is yellow and above is green) – below this power application is limited as the engine is warming up

Max. continuous 160°C (320F) (below is green and above is yellow)

Max. 180°C (356F) (red line)

The temperature of the cylinder head is determined by the heat energy coming from the combustion chamber and the cooling effect of air and oil over the heads themselves. The sender is generally a K type thermocouple that generates a small voltage based on the reaction of the different wires where they are joined at the sensing end. They can simply be wired to a suitable instrument. (If you prefer not to wire them yourself, the ULP AUX box is available – contact your local agent for more info)

ULPower does not need to use the ‘under the spark plug” ring type CHT units, as the ULPower cylinder head is machined to take the more robust and reliable ‘bayonet spring’ type. Installed correctly, these are the best source of accurate CHT data, based on field experience.

CHT is controlled by air-flow. If the inlets and outlets are not right, the CHTs won’t be right either. Because the cylinder heads are partially cooled by oil jets into the rocker cover area, we find that head temperatures are generally lower than similar installations without this feature.

So, how do we install the bayonet sprung CHT senders?

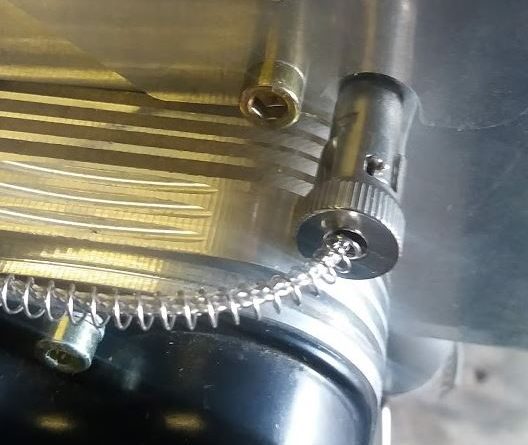

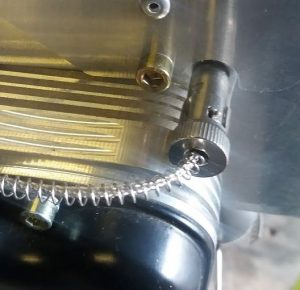

Above each rocker cover there is a tapped hole to take the CHT sender

Screw the carrier in, if necessary, you may need to use a wide, slim screwdriver or similar to gently nip it into place – without damaging the unit.

Next you must ‘screw over the spring’ the bayonet cap backwards or forwards to expose enough lead so that when the sender bottoms out in the hole there is about 10mm (3/8″) of gap between the cap and the fitting before compression. It is important that the sender touches the bottom of the hole !

Gently push the spring in and turn the bayonet cap to secure.

This system keeps the sender in contact with the cylinder head material, resulting in more reliable and consistent readings.

The ULPower Troubleshooting guide (available from www.ulpower.com) notes several factors that may affect CHT values, including

FAULTY SENSOR OR INCORRECT SETTINGS ON INSTRUMENTS

NO SPARK OR NO FUEL INJECTION

RAM AIRBOXES NEED MODIFICATION

BAD VALVE CLEARANCE SETTING

LOW OIL LEVEL

ETC

If you haven’t downloaded the interactive guides for maintenance and troubleshooting, now is the time to do so!

If you are unsure about any aspect of your installation or troubleshooting, contact your local ULPower Dealer who will be ready to help you!