Changing the Throttle Body

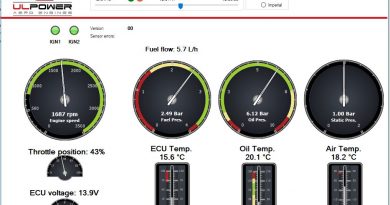

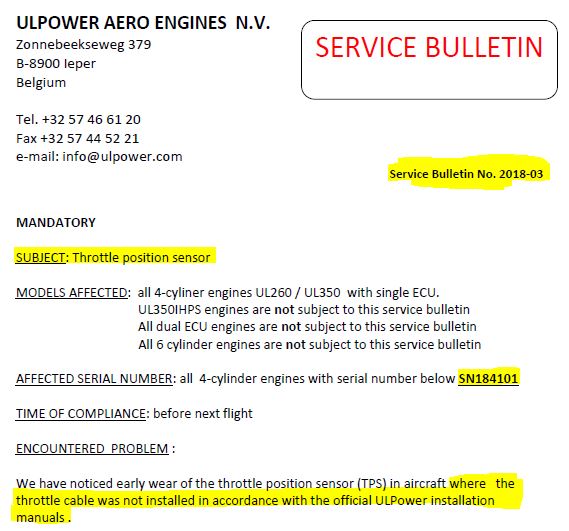

All ULPower engines, from Serial number 184101, are now being delivered with a new style throttle body with a ‘HALL EFFECT’ Throttle Position Sensor (TPS). Existing engines that do NOT have the Hall effect sensors, may choose to upgrade, or may need to upgrade if their throttle mechanism does not conform to the installation manual. This is covered in detail in the Service Bulletin 2018-03 available here service-bulletin-2018_03 … This has led to questions about how to change the throttle body, which we will cover in this article…

The original TPS had a track that was in contact with a moving arm – sometimes called a ‘wiper system’, and when installed in a manner that permitted vibrations to constantly play on the arm/track had been shown in rare cases to lead to early wear in the part. The new TPS has no contact points, and hence a much longer life. It can now be installed using an even wider variety of throttle control systems.

Do note that a change from the old type of TPS to the new type does require a change to the ECU mapping (due to the position values being different between the two sensors). DO NOT CHANGE THE THROTTLE BODY TYPE WITHOUT UPDATING THE ECU. You should contact your local ULPower dealer or see the SB for details of where to send your ECU for the update.

If you need to, or simply choose to, change your throttle body the procedure is very straightforward and we are going to look at how to do that here:

- Layout your parts and tools:

Torque Wrench

Socket Wrench

4mm Allen Key (with adapter)

Elring Sealant (Elring n°030.790 or 030.792)

New throttle body

Adapter cable

plus some tie wraps/side cutters, etc

You may want to look at the Illustrated Parts Catalogue for your engine too!

-

Disconnect the throttle linkage and remove the air filter/scat hose from the old throttle body and then carefully disconnect the TPS

- Remove the 4 Allen bolts holding the throttle body in place, slacken in a crosswise manner.

- If required GENTLY tap on the old throttle body with a soft (nylon or rubber) hammer, whilst supporting it, to release the Elring sealant bond

-

Clean up the mating surface using a cloth or rag (use a little methylated spirit if needed) – avoid the use of paper towels as they tend to leave debris behind.

UNDER ALL CIRCUMSTANCES MAKE SURE NO DEBRIS ENTERS THE AIRBOX! If it does, clean it out before continuing!!!

- To make application of the Elring sealant easier, use a tie wrap to hold the throttle closed

- Put a little Elring on the surface and use a small hard roller, or a roll of tape (or anything with a smooth surface) to pick up a film of sealant. Transfer it to the throttle body in a uniform manner. NOT TOO MUCH but all the surface must have some on. Make sure you do not get any on the butterfly!

- Carefully mate the new throttle body to the airbox, and insert the 4 allen bolts spinning in to ‘contact’ by hand.

- Set your torque wrench to 6Nm

- Tighten then torque the bolts in a criss cross pattern.

- There should be a SMALL bead of sealant extruded to the outside of the throttle body. There is no need to wipe this away.

CAUTION: If you have ‘splodges’ of sealant extruded it may mean that you put too much on.

IF you have too much extruded to the INSIDE of the throttle body it may cause issues.

If you put too much on, take the throttle body off, clean both faces and start again! - Supporting the throttle mechanism (so that it does not spring back violently) cut the tie wrap holding the butterfly closed. Remove the tie wrap from the engine area.

- Look down through the open butterfly for any signs of ‘over extrusion of sealant and check for proper movement of the butterfly valve from fully open (shown) to closed.

- Connect the TPS adapter to the old connector on the engine loom.

- You will note that the new throttle body has TWO Hall sensors. You can connect the other end of the adapter to either TPS connector. (ULPower use the same throttle body for the Dual ECU engines, that is why there are two!) We suggest putting tape over the end of the unused connector (which acts as a ‘spare’ connector should it ever be needed)

- Tie wrap the adapter and cables into position and ensure that there are no risks of catching the wires.

- Reinstall scat hoses/air filters, throttle cable, etc and clean up your work area, re-install cowls, etc and ground test your engine whilst following all safety procedures!

REMEMBER you must have updated your ECU to the map for the new Throttle Body BEFORE you run the engine!

If you are unsure, you should always ask your ULPower dealer for details of approved service points near you.

The ULPower.news team believe that the move to a Hall Sensor TPS is a positive one!

We would like to remind those with the old sensor that field experience has shown that it works great when installed in accordance with the manuals – take a look at the service bulletin for more details on that!